Automatic cutting machine for vegetables and fruits – FOODCONS FS-3600 multiSystem

Slicing and wedging

The FS-3600 multiSystemis the expanded version of the FS-3600 multiCut. The new special feature is the coordination of a cut product in a predictable quantity through sensor-controlled programming, easily controllable through intuitive operation on the new touchscreen and with a selection of conveyor belts.

The new conveyor belts complete the process-related selection options, including the tray belt with new direct filling and ergonomic working height.

Suitable for:

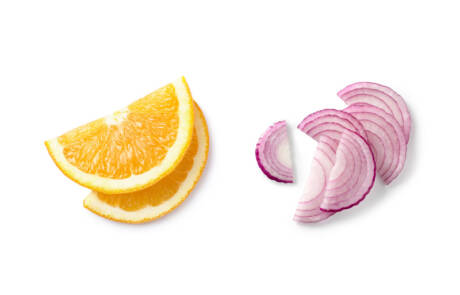

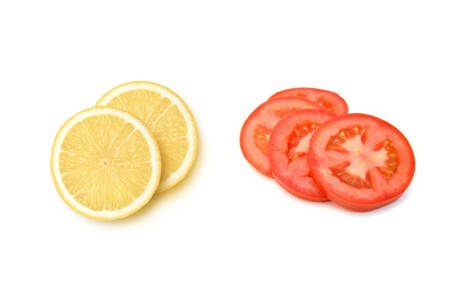

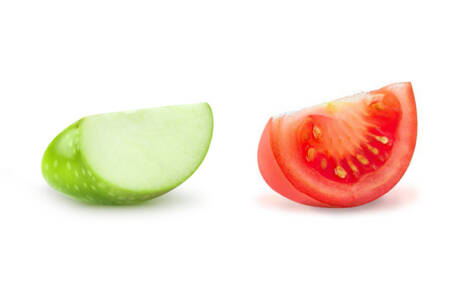

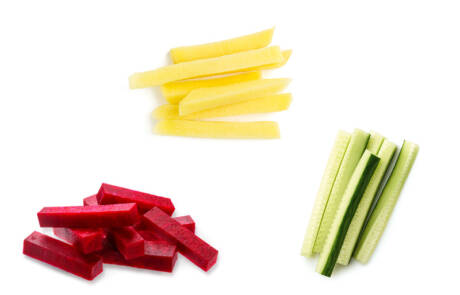

Cutting impressions:

The FS-3600 multiSystemis the expanded version of the FS-3600 multiCut, which optimizes the entire process and can be designed entirely according to the operator’s wishes. Fruits and vegetables can still be cut into wedges, cored wedges, slices, halved slices and sticks; depending on the size, up to two products at the same time.

The innovative automatic cutting machine sets new standards in hygiene, simplicity of operation, speed of tool change, high capacity, multifunctionality and the perfect cutting result. The new special feature is the coordination of a cut product in a predictable quantity through sensor-controlled programming, easily controllable through intuitive operation on the new touchscreen and with a selection of conveyor belts. For example, trays can be filled directly, with a defined quantity of cut products using the new sensor-driven product counter. The new intuitive touchscreen simplifies the programming, selection and operating process and assists the operator, for example, in selecting the trays and filling quantities. In addition to the tray band, there is of course the (improved) standard band and the cup band. The cup band holds the individual product in a round device with flexible fingers and is optimal for removing an entire cut product. All conveyor belts are brought to an ergonomic removal height of 860 mm thanks to the new Z-shape and thus makes the work process easier.

The basis of the FS-3600:

The base frame consists of an open frame. In addition, the FS-3600 has hinged doors through which the cutting room is fully accessible. The control cabinet can easily be folded away for cleaning or maintenance. Using quick-change systems, the cutting sets and ejector units can be exchanged extremely quickly.

Blade for slices

Cutting width: 4,5 – 30 mm

Max. product diameter: 100 mm

Max. product length: 140 mm

Blade for wedges

2, 4, 6, 8, 10, 12, 16 wedges

Inner diameter: 98 mm or 114 mm

Coring tube: 20 mm, 25 mm, or 30 mm

Grid blade

20 – 30 mm

Endpiece separation

To separate slices from end pieces and cores from apple wedges.

Safety covers

Safety covers for wedges and grid blades

Product trolley and tool trolley

The product trolley can be equipped with two boxes of raw products.

The tool trolley can be used to safely store three complete cutting sets.

Installed capacity:

FS-3600: 1,2 KW

TBS-1500: 0,3 KW

Terminal voltage:

230/400V, 50/60 Hz

Dimensions (L x W x H):

FS-3600: 1110 x 930 x 1790 mm

TBS-1500: 2110 x 580 x 720 mm

Weight:

FS-3600: appr. 350 kg

TBS-1500: appr. 50 kg

Capacity:

up to 3600 pieces per hour